MAAC Rotary Twin Sheet

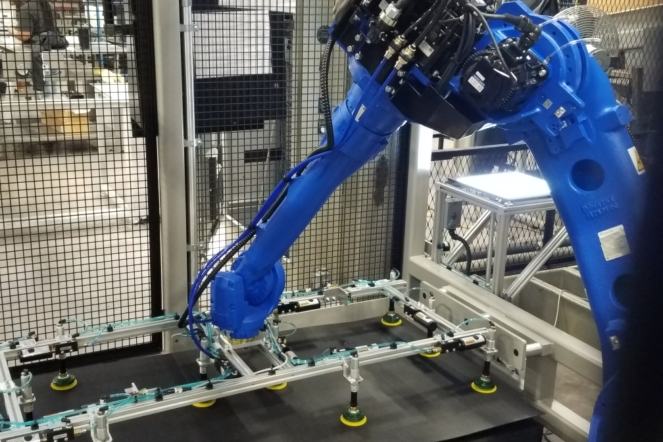

Twin sheet pressure forming is done with machinery specifically designed for this process. MAAC single oven rotary twin sheet pressure forming machines (R3PT, R4PTU & R4PTC) are designed to use the single-oven twin sheet technique. This process consists of two sheets to a frame; one upper, one lower, and a single index. MAAC Four Station Double Oven Rotary Twin Sheet Pressure Forming machines (R4DPT) can utilize the single-oven twin sheet technique and the double-oven twin sheet technique. The double-oven twin sheet technique is used in applications that require either a plug assist, inserting or thicker materials. This process consists of one sheet to a frame and a double index, with the first sheet retained by the bottom mold. MAAC Rotary Twin Sheet machines feature our heaviest and most accurate, “zero deflection”, air cell lockup high pressure forming platens and are available with multiple control system options.

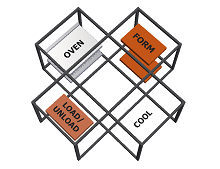

Configuration Options

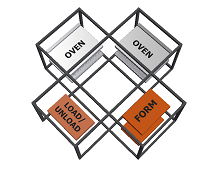

Four Station Double Oven Rotary Twin Sheet Pressure Former (R4DPT) Most popular double oven twin

sheet machine.

Four Station Double Oven Rotary Twin Sheet Pressure Former (R4DPT) Most popular double oven twin

sheet machine.

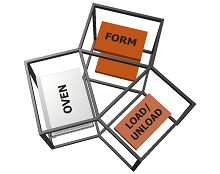

Three Station Rotary Twin Sheet Pressure Former (R3PT) Most popular for single oven twin sheet.

Three Station Rotary Twin Sheet Pressure Former (R3PT) Most popular for single oven twin sheet.

Four Station Rotary Twin Sheet Pressure Former with Unload Station (R4PTU) Single oven twin sheet machine with an unload station.

Four Station Rotary Twin Sheet Pressure Former with Unload Station (R4PTU) Single oven twin sheet machine with an unload station.

Four Station Rotary Twin Sheet Pressure Former with Cooling Station (R4PTC) Single oven twin sheet machine with a cooling station.

Four Station Rotary Twin Sheet Pressure Former with Cooling Station (R4PTC) Single oven twin sheet machine with a cooling station.