MAAC Shuttle Twin Sheet

Twin sheet pressure forming is done with machinery specifically designed for this process. MAAC Single Station and MAAC Double Ender Twin Sheet machines are designed to use the single-oven twin sheet technique. This process consists of two sheets to a frame; one upper, one lower, and a single index. MAAC Shuttle Twin Sheet machines feature our heaviest and most accurate, “zero deflection”, air cell lockup high pressure forming platens and are available with multiple control system options.

Configuration Options

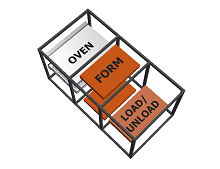

Single Station Twin Sheet Pressure Former (SPT) Single oven twin sheet machine. Material is loaded and unloaded in the form station.

Single Station Twin Sheet Pressure Former (SPT) Single oven twin sheet machine. Material is loaded and unloaded in the form station.

Single Station Twin Sheet Pressure Former with Load Station (SPT-L) Single oven twin sheet machine with a dedicated load/unload station.

Single Station Twin Sheet Pressure Former with Load Station (SPT-L) Single oven twin sheet machine with a dedicated load/unload station.

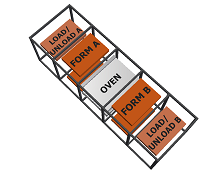

Double Ender Twin Sheet Pressure Former (DEPT) Single oven twin sheet machine. Incorporates a 2nd form station for increased production.

Double Ender Twin Sheet Pressure Former (DEPT) Single oven twin sheet machine. Incorporates a 2nd form station for increased production.

Double Ender Twin Sheet Pressure Former with Load Stations (DEPT-L) Material is loaded and unloaded in dedicated stations for each side.

Double Ender Twin Sheet Pressure Former with Load Stations (DEPT-L) Material is loaded and unloaded in dedicated stations for each side.